As more and more manufacturers turn to data-driven processes and automated solutions, lidar’s potential in the industrial manufacturing sector continues to grow. From monitoring product quality and facility conditions to powering autonomous vehicle navigation, lidar can improve safety, efficiency, accuracy, and performance for many manufacturing applications. Learn more about how 3D lidar adds value to industrial manufacturing with this brief overview.

Improving Equipment Sensors and Navigation

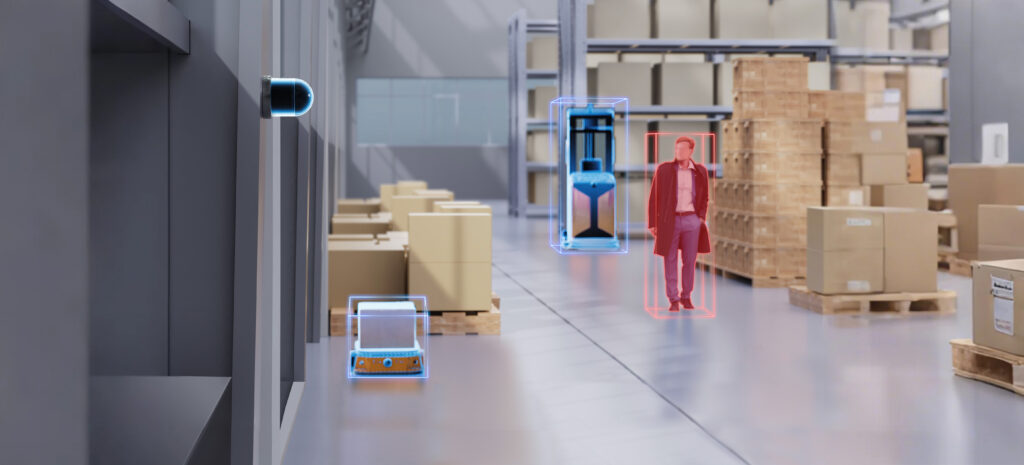

Autonomous vehicles and mobile robots—such as automated guided vehicles (AGVs)—are must-haves for facilities to stay efficient and flexible in an ever-changing industry. However, these autonomous applications only work with reliable navigational systems.

3D lidar sensors improve navigation through a comprehensive and detailed point cloud of the vehicle’s surrounding environment. Through advanced lidar systems, AGVs and other autonomous applications can move safely through a facility while avoiding collisions, traffic jams, and other hazards that slow your workflow.

Efficient Surveying of the Manufacturing Plant

Surveying is a necessary step for advancing facility improvement projects. While traditional surveying techniques can take a significant amount of time, 3D lidar can streamline the process with a detailed scan of the entire facility. Lidar offers more precise measurements than traditional surveying, making it invaluable for documenting a facility’s existing conditions or planning upcoming projects.

Ensuring Quality and Compliance

Quality control is a crucial part of any manufacturing process, but it can create bottlenecks at the end of your production line. Fortunately, you can implement quality control in every step of the workflow with lidar. In addition to creating more thorough quality control standards, it also ensures compliance during every stage of manufacturing.

Lidar’s immense precision catches mistakes and anomalies that workers and supervisors might miss. Additionally, real-time data allows employees to correct those mistakes immediately, preventing issues down the line. Lidar-based quality control is excellent for repetitive processes that rely on consistency. It also supports vital industries—such as pharmaceutical or automotive manufacturing—that rely on immense safety and compliance to create reliable products.

Are you interested in learning more about the valuable role 3D lidar plays in industrial manufacturing? Explore cutting-edge industrial safety lidar sensors and learn more about lidar in the industrial sphere at Hesai Technology.