Advanced Driver Assistance Systems (ADAS) continue to revolutionize the driving experience. As more manufacturers incorporate ADAS features into their vehicles—and as those features continue to evolve and expand—the need for ongoing ADAS maintenance becomes more prevalent. Knowledge about ADAS operation and maintenance needs must become more common and accessible to ensure that drivers can continue to get the most out of their ADAS and stay safe on the road.

One crucial ADAS maintenance need is calibration. Without proper calibration, features like sensors and cameras are unable to properly obtain and process data about the vehicle’s surrounding environment. Discover everything you need to know about ADAS sensor calibration and the role it plays in a functional ADAS system.

ADAS Calibration Explained

ADAS calibration is the process of physically aligning the sensors, cameras, and other features that make up the system. During the manufacturing process, professionals align these features to factory standard positions so that all new vehicles have precise and accurate sensors for consistent ADAS performance.

Over time, however, road accidents, vehicle maintenance, and other changes can knock these sensors and cameras out of alignment. When sensors are out of alignment, they can’t accurately process the data they obtain. ADAS sensors and cameras power tools like automated parking, lane assist, adaptive cruise control, blind spot monitors and warnings, and other crucial safety features. As a result, calibration is an immensely precise process that requires physical alignment, electronic aiming, and thorough testing to ensure success.

The Calibration Process

All ADAS calibrations start with a pre-scan to figure out how the sensors are currently operating and how far off the alignment is. From there, technicians make manual adjustments to position each sensor or camera in approximately the right area. After that, the ADAS module itself performs more precise, electronic adjustments to fine-tune the alignment. Once everything is in place, technicians conduct a post-repair diagnostic scan to make sure everything looks and performs as it should.

Static vs. Dynamic Calibration

There are two forms of ADAS calibration: static and dynamic. Static calibration occurs when the car is in a fixed position within a controlled environment. Dynamic calibration requires the vehicle to be in motion. The type of calibration you need—static, dynamic, or both—will depend on the type of vehicle as well as recommendations from the original equipment manufacturer.

Static Calibration

Technicians require precise tools and conditions for a successful static calibration. Static calibration equipment includes an ADAS scan tool for diagnostics, an ADAS calibration tool and alignment rack, an aiming target (or targets, depending on the vehicle), and measuring tape or lasers. Additionally, static calibration must occur in a controlled environment. This means an open space with zero obstructions, a level floor, uniform wall and flooring color, consistent and adjustable lighting, and no sunlight. The space should also be free of any reflective surfaces to avoid interference with the sensors and cameras during calibration.

Dynamic Calibration

Some vehicles just use dynamic calibration, while others add dynamic calibration as an extra step at the end of the calibration process. Dynamic calibration ensures that all sensors and cameras are properly aligned while the vehicle is in motion. Think of it as a field test for the ADAS equipment.

During the dynamic calibration process, technicians operate the vehicle with the ADAS scan tool attached. They test specific parameters, such as driving at certain speeds, following other vehicles, or driving along clearly marked roads. During the drive, the scan tool detects objects and markings along the road and calibrates the sensors and cameras as needed.

The Frequency of ADAS Calibration

As with any vehicle maintenance task, it’s important to know when ADAS calibration is necessary. The answer changes from vehicle to vehicle. The location of the sensors and cameras is a huge factor. For example, if your ADAS sensor is mounted on or behind the windshield, you will need a recalibration any time you replace the windshield. The same goes for bumpers, which are another common location for ADAS equipment.

Accidents—even minor ones—are another common reason you might need a recalibration. If your vehicle takes damage or needs repairs in an area where ADAS sensors are located, it’s a good idea to at least check the calibration to ensure the system continues working as intended.

Additionally, modifications that change the ride height of your vehicle affect the accuracy of your sensors and cameras and therefore require ADAS recalibration. Thankfully, most systems have built-in sensors that light up or otherwise notify you when the system needs calibrating.

Calibration Needs Change with the Vehicle

Understanding the specific needs of each vehicle’s ADAS equipment is a significant part of what to know about ADAS sensor calibration. ADAS features vary from vehicle to vehicle, resulting in a different calibration process for every make and model. Some features, like sonar-based parking sensors, tend to require calibration less frequently than other parts of the system. Most of the time, calibration involves ADAS cameras or radar and lidar sensors.

ADAS Cameras

ADAS cameras—including blind spot, rearview, and forward-facing lenses—help the system identify objects, monitor lane markings, sense light levels, and more. They play a crucial role in ADAS features such as adaptive cruise control, automatic emergency braking, lane assistance, and parking assistance. Proper camera calibration allows the system to accurately identify which part of the camera’s image it should pay attention to. The camera can then differentiate between harmless traffic signs that you can drive past with no trouble and oncoming obstacles that require a reaction from you or the vehicle.

ADAS Sensors

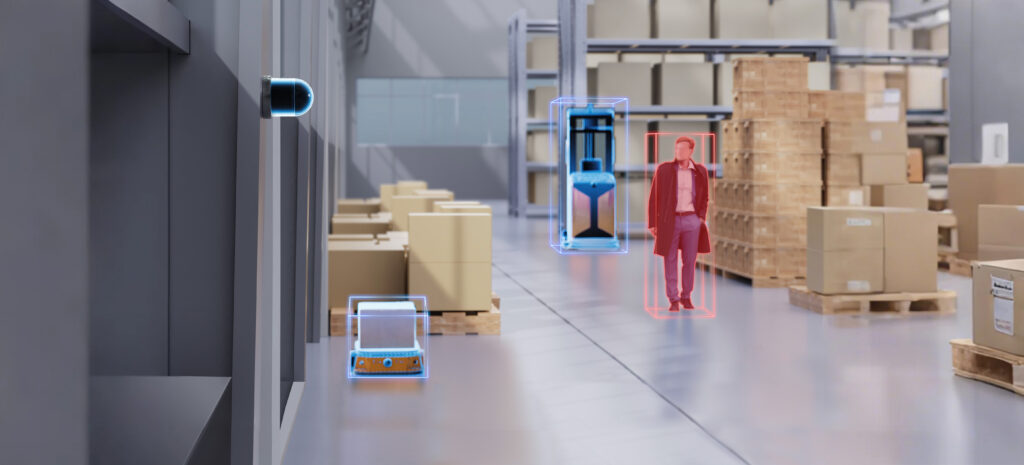

Sensors like lidar and radar systems also require proper calibration after a collision or other incident that impacts the area of the vehicle where they’re located. These sensors include both rearview and forward-facing options that power features like adaptive cruise control, forward collision warning, blind spot monitoring, and more.

The Future of ADAS Services

ADAS features are continuing to revolutionize safety, convenience, and comfort for drivers around the world. As these systems continue to evolve, developers like Hesai Technology strive to meet new demands with advanced lidar sensor technology. Our cutting-edge solid-state lidar systems power safety, accuracy, and continuous innovation in advanced driver assistance systems. Visit us today to learn more about our work in ADAS technology and other revolutionary vehicle applications.